Membrane bioreactor (MBR)

Membrane bioreactor (MBR) is a high-tech water treatment technology that combines membrane separation technology and biochemical reactions in traditional wastewater treatment technology, also called membrane separation activated sludge process.

Membrane bioreactor (MBR) is to use membrane to filter water containing activated sludge biochemical in reaction tank, so as to achieve separation of sludge and water. On the one hand, membrane retains the microorganisms in biochemical reaction tank, greatly increases the number and types of beneficial bacteria in biological phase, so that the biochemical reaction of pollutants degradation is conducted more rapidly and completely, on the other hand, due to the high filtration degree of membrane, produced water quality is greatly improved.

MBR technology’s advantages:

- Good and stable water quality.

- Less residual sludge, reduce sludge disposal costs. Generally about 30% of sludge is reduced than the conventional activated sludge process.

- Modular design, compact structure, land occupying about 30 ~50% less than the traditional process.

- Due to the membrane’s effective retention role, microorganisms are completely retained in the reactor, SRT is no longer subject to the impact of sludge amount, SRT can be flexibly controlled.

- Strong resistance to impact load. The concentration of microorganisms in the reactor is up to 5~8 g/L, so the system volume load is high, and resistance to shock loading is strong.

- Can effectively remove ammonia nitrogen. The SRT growth is beneficial to detention, growth and reproduction of nitrifying bacteria with slow proliferation, so system nitrogen removal is effective.

- Convenient operation and management, and easily automation control. With PLC control, full automation can be achieved.

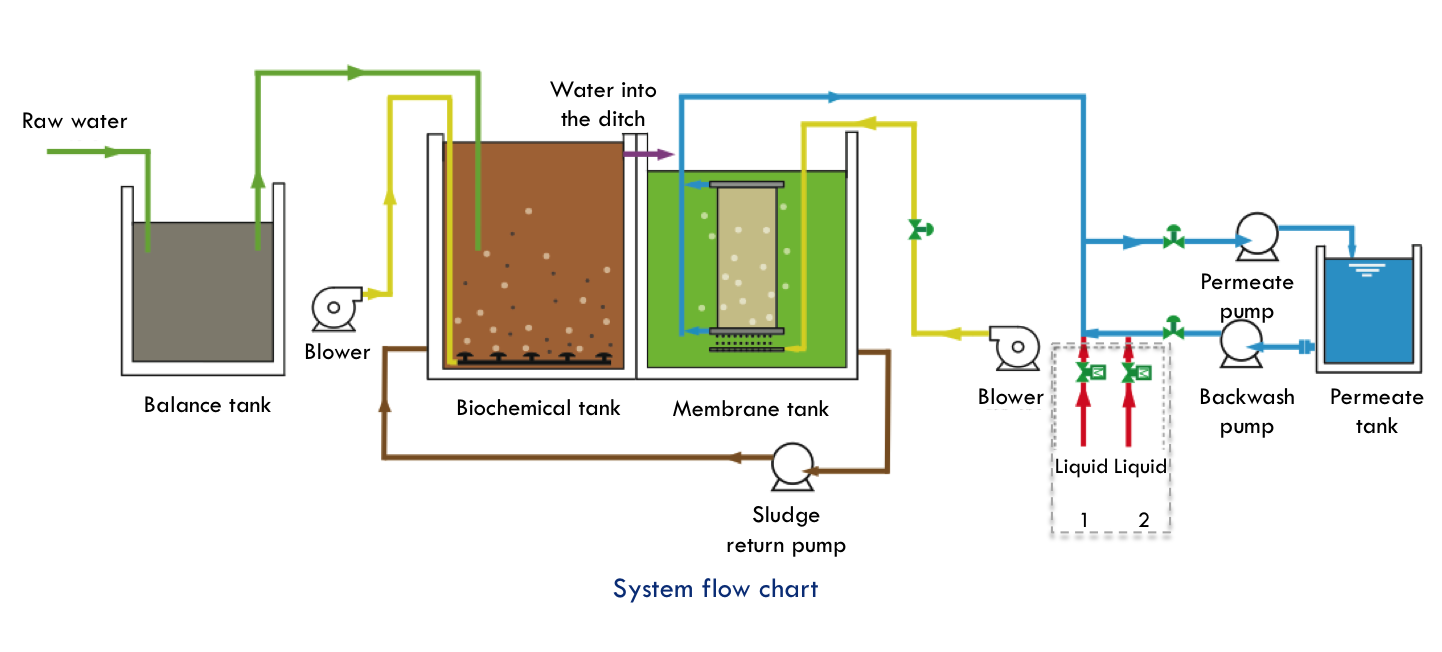

MBR system composition:

Typical MBR system is usually composed of two parts:

- biological treatment system

- membrane separation system.

In the field of wastewater treatment, the most commonly used MBR system is generally composed of :

- pretreatment system

- biochemical systems

- aeration systems

- membrane filtration systems

- membrane cleaning system

- control system

- sludge dewatering system.

Figure: MBR system flowchart

Membrane bioreactor (MBR) products:

|

|

|

|

|

|