Automatic self-cleaning disc filters

- Thin color-coded polypropylene discs are diagonally grooved on both sides to a specific micron size.A series of these discs are then stacked and compressed on a specially designed spine.

- When stacked, the groove on top runs opposite to the groove below, creating a filtration element with a statistically significant series of groove and shoulder, which trap the solids.

- The stack is enclosed in a corrosion proof and pressure resistant housing.

- During the filtration process, the filtration discs are tightly compressed together by the spring’s power and the differential pressure, thus providing high filtration efficiency.

- Filtration occurs while water is percolates from the outer diameter to the inner diameter of the element.

- Depending on the micron rating, there are from 18 (in 400 micron discs) to 32 (in 20 micron discs) stopping points in each track, thus creating the unique in-depth filtration.

The advantages of disc filter:

- Super-speed and back washing

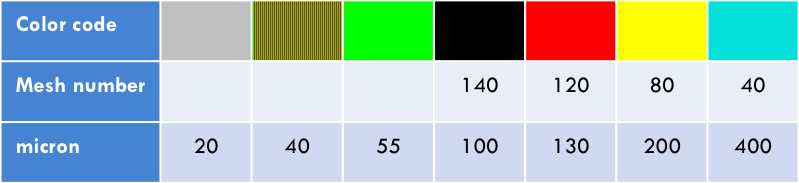

- Stable filtration efficiency with different precision: 20um, 40um, 55um,100um, 130um, 200um, 400um

- Technical characteristics of accurate filtering and continuous filtration

- Easy operation and assembling, low cost of maintenance

The materials of the filter:

- Filter shell: Reinforced nylon, PP, stainless steel, carbon steel

- Filter element: Nylon, PP

- Filter disc: Nylon, PP

- Flush valve: Reinforced nylon

- Solenoid valve: Brass

- Exhaust valve: Reinforced nylon

- Piping system: Carbon steel

- Control line and connector: PP

Color code and accuracy of discs:

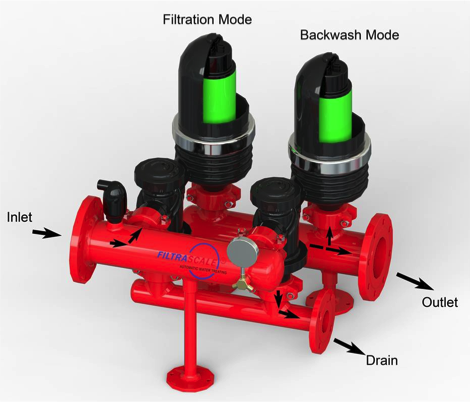

Filtration process:

- The discs are compressed together by both the spring and the pressure difference on the tightening cap, forming a sturdy filter element preventing solids breakthrough.

- Inlet water flows into the filter through the filter element.

- The suspended solids in the water are trapped on and between the discs.

Backwashing process:

- A command from the control unit to the filter’s inlet valve causes the value to close the filter’ inlet and open the drain.

- Filtered outlet water enters from the opposite direction through the outlet port of the filter.

- The flaps of the membrane are opened by the water pressure, allowing the water to flow only into the 3 flushing pipes.

- The water is forced through nozzles built into the flushing pipes.

- Water from the flushing pipes also flows into the piston and pushed the tightening cap up, decompressing the filtration element discs.

- Tangential jets of water cause fast spinning of the separated discs and remove the trapped solids.The solids are flushed from the filter to the drain.

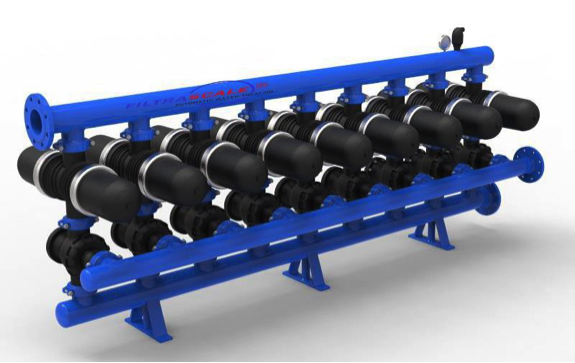

Models:

| 2″ automatic self-cleaning disc filter | 3″ automatic self-cleaning disc filter |

|

|

| 4″ automatic self-cleaning disc filter | – |

|